Refurbishment of Cooling Towers

The cooling tower is equipment that has as a goal to dissipate a certain amount of heat as a function of time, designed to meet the demand that the customer requires in their process, in terms of heat dissipation, or simply, cooling. It is common for some people to confuse the real purpose of a tower, incurring in wrong decisions: in situations where production expansion occurs, demanding more tower dissipation power, exceeding its initial design, and so the tower is not working properly. There are those who invest in maintenance, when in fact the problem is different: refurbishment of the tower, to adapt to the new reality of the client.

What is retraining?

Refurbishing, repowering, increasing efficiency or simply improving the cooling tower, consists of increasing its thermal dissipation capacity. In simple terms, if a tower has a capacity of 30,000 kcal/h, after refurbishing it will have, for example, 35,000 kcal/h. However, the way to increase the thermal capacity of a tower is not so simple, as some people say: you cannot just change components such as contact filling, sprinkler nozzles or the axial fan, without first analyzing and studying the case correctly. There are cases in which the cheap is expensive: in addition to the cost of replacing components, the cooling tower ends up losing performance, generating losses for the customer.

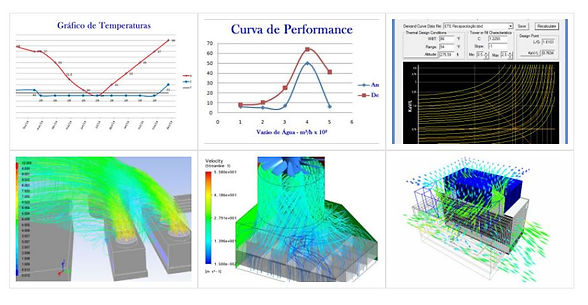

The AW Group has adequate tools and qualified technical staff to carry out the study on the refurbishment of cooling towers, ensuring an increase in the efficiency of the cooling tower after the intervention.

Refurbishment X New Towers (Additional)

There is a common doubt between refurbishing the tower, or existing cooling towers, and purchasing a new tower and adding it to the existing towers. There is no rule for this, nor a simple formula. It is necessary to study and analyze it case by case. However, we can mention some differences between refurbishment and acquisition of new towers:

Floor space and layout: A new cooling tower will obviously require more floor space. However, it is not just the space of the new tower: it is necessary to analyze the physical space available for the new hot and cooled water pipe, the construction of the civil base (masonry) of the new tower, the space around it (minimum distance required by the tower to ensure its functioning ) among other details. This is a determining factor for decision making, as even if the customer currently has physical space, it cannot later be used for expansion of the manufacturing process, new production lines or any other, as it will be occupied by the new tower.

Piping: a new tower will require a change in the hot and chilled water piping, which is currently installed at the customer. Often this means a complete stoppage of production to adapt the pipe. The refurbishment, on the other hand, requires only one cooling tower stopped at a time, allowing the process to proceed normally while the towers are rebuilt, in stages, and do not require any changes to the piping.

Electrical installation: a new tower added to the process will require a change in the current electrical switchgear for the towers, for the new hydraulic and ventilated pumps for the towers. This implies an analysis of both technical and operational feasibility, as well as economic: often the framework does not have space for increasing components.

Time: the design of a new tower, and its execution (manufacturing the tower and its components, transporting it to the installation site, assembling, testing and commissioning), if carried out correctly, demand a certain amount of time, according to each case. By comparison, retrofitting cooling towers requires less design and deployment time. In some cases, retrofitting (from design to execution) takes only 30% of the time for a new tower.

Costs: Last but not least, there is also the cost factor. From the items above, it is possible to have a comparative idea of costs, which deal only with the “peripheral” adjustment in the comparison between refurbishing or acquiring a new tower. The costs of acquiring the new tower and refurbishing are also taken into account, of course. It is necessary to consider all the costs involved in each case, as it is not just possible to compare the cost of a new tower with a refurbishment: it is necessary to take into account the transport and installation of the new tower, in addition to the aforementioned items.

However, the AW Group reinforces that there is no simple rule or formula: it is necessary to analyze each case, as it is not a simple equipment that can be marketed as a “repowering kit”, promising efficiency gains without technical criteria. Obviously, each equipment has its operational limit. AW Group has full experience in this matter, and always recommends the most viable solution to the customer.

Contact us for more details. contato@awgroup.com.br